Yankee Industrial – Distribution by Design

History

Yankee Industrial Supply is a company with over 30 years’ experience in the fastener business. In 1995 Leonard and Lempi Petit moved Yankee into a 4,500 square foot leased facility and shared the space with about 2,000 square feet of machine shop. In 1998 Yankee was sold to Nathaniel “Bud” Durgin and he quickly focused on the distribution of fasteners.

State Of The Art Computer System

Bud Durgin said, “We purchased a state of the art computer system that specialized in fastener distribution. This system enabled us to provide a great number of services to our customers such as customer part number identification, customized bar code labels, managed processes such as plating, patching, and specials. It also provided tools to create, track, and organize special value added services such as “kitting” for customers.”

Much Larger Now

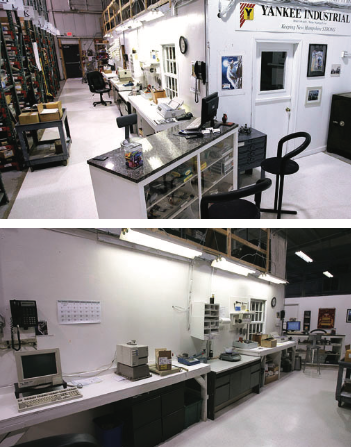

Today Yankee is located in a company owned facility with over 18,000 square feet and they have plans to expand their products and services further in the near future. Bud stated, “All fasteners are almost the same. The difference is going to be realized in the experience our customers see in the way we handle their calls, the inventory levels we carry, the packaging and presentation of materials that accompany our products, and of course the value we add to everything we do.”

Great Place To Work

Bud said that their people make a big difference. “We strive to make Yankee a great place to work and we have made major investments in inventory, equipment, and facilities that support our quality team of associates at Yankee. The objective of our business is to provide world class quality in both products and services that we perform for our customers. Our growth is governed by our ability to maintain a level of service that meets our customers’ expectations.”

The Learning Years

Bud said, “I was an average kid in school, I spent most of my free time working – even as a young lad. It started out with shoveling the neighbors’ snow to yard cleaning, to paper routes, and eventually into the “precious metals business.” At a young age we would rummage through large scrap piles behind a Sylvania Light

Bulb factory about a 1/4 mile from my home. We would dig out light bulb bases, knock the glass out and crush them into collections of brass that we sold to a local scrap yard. I think the field is now a super fund site.”

Accounting Made Sense

Bud said, “The subjects I enjoyed in school were accounting, math and the sciences. My high school accounting teacher (Charlie Murphy) brought me to the bulletin board in our class and pointed to an ad for an Accountant that had an annual salary of $17,000. That was it – I knew what I wanted to do – become an Accountant. I think that was the first class I ever received an A in.”

Looking For Direction

After nearly twenty years serving as a Vice President of Operations working at the Toyota Port Facility in Boston, Bud decided it was time for him to use his acquired skills in his own business. His specialized training in the Toyota Production Systems, Kaizen, and Lean Manufacturing provided him with a vast amount of skills that he was eager to put to use. He started searching for a new direction in life and he came across a local ad for a business 8 miles from his home that was for sale. He contacted the owners, Leonard & Lempi Petit and after it became evident that it might be a good fit, asked if they would mind if he worked free for a week to get a feel for the business.

Typical Fastener Experience

It turned out that it was a typical fastener company experience for the time. It was not easy. The phone would ring and the customer would ask “do you have …”. He would have to place them on hold, walk into the warehouse, go to the section and look for a box or a bag of parts… “Yes, we have some”. They sometimes would ask “how many have you got?”… Repeat the process – this time bringing the parts to the scales and counting them out. “We’ve got…”. Customer – “good – how much are they”. This is where it got difficult. “hold on” … he would pull out the three ring binder – find the matrix based on the type of fastener, material, diameter, and length…”they are… each”. Now, if it was a certain customer who had special pricing there was another binder. This one had large ledger sheets with “contract pricing”. He would have to scan through pages and pages of sheets looking for the part. After a few hours he thought to himself “this is nuts, no wonder these people want to sell.”

Technology Was The Answer

It didn’t take him long to realize that there were some great opportunities here. He kept thinking about what it would be like if they had the tools to better manage this. It took longer to produce a hand written order than it did to fill it, not to mention that all invoices were “hand written” and very unprofessional. Leonard and Lempi had a great customer base but were considered a secondary supplier by many accounts. Bud used to joke that customers would come to Yankee with their trunks dragging on the ground due to the weight of fasteners looking for the few parts their primary supplier did not have. He wanted to change that. He wanted to become the primary supplier and knew that he needed to get organized in order to even think about doing that. They needed a computer.

Custom Program

One of the first things he did was bring in a computer programmer from his Toyota days to help him look at getting this information together. It didn’t take long to realize that this project was big. Way too big for a whiz kid programmer.

Vertical Market Software

He started to reach out to other fastener distributors and found a system that at the time seemed to be the system that most of the big distributors were using. They spent about $60,000 on hardware, software, training, and forms for the new system. At the time Yankee was so small he was not taking a salary, and sixty thousand dollars was quite a bit of money, and a high percentage of their annual sales.

Vendor Managed Inventory

With the new software the company was on the right path and soon integrated the Vendor Managed Inventory (VMI) into his operations. With the ability to cross reference customer part numbers, print bar code labels, it allowed Yankee to provide a great value of service to some of the larger accounts. The VMI program has allowed customers to stop trying to track inventories of fasteners, reduce purchase order creation related expenses, and has allowed buyers and planners much additional time to spend on more critical inventory matters.

Software Getting Old

After 17 years with that software and countless revolutions of the hard drive he knew that they were operating in the danger zone. The company that they purchased the system from sold out about 5 years after they signed. Then it was resold or bought out a few more times. Support for their system stopped, there were no more improvements nor updates and despite the fact that the annual support fees kept coming. When he questioned “what are we paying for” he was told it was the ability to get support in the event of a problem. If they ended the support but needed it at a later date it would be extremely expensive to reinstate. Their current support rate was grandfathered in. They wanted Yankee to upgrade to the vendor’s new system. Bud said “No thanks – I don’t do businessthatway. Itoldthereceptionist“nexttimeDenny calls put him through”.”

The Business Edge™

Denny Cowhey is with Computer Insights (CI). Their software, The Business Edge™, was runner up to the other software for us back in 1998. Bud said, “I used to joke with Denny that he was wasting his time when he called regularly to check on our status. In the summer of 2014 I realized that our system was now holding us back. Our foundation was in trouble. Customers wanted things (quotes, confirmations, invoices) emailed. Our system only had the capability to print or fax. We found ourselves faxing to ourselves, scanning documents in order to email. It kind of felt like I was back in early 1998 handwriting invoices. Way too much time was spent on mundane things as standing in front of a scanner. Many aspects of the old system were outdated and became problems”

Easy Transition

He also said, “The transition to our new computer system, The Business Edge™, by Computer Insights was flawless. A former employee of our original software company, Cheryl Patchett was assigned to our account to assist us with the setup of the new system parameters, assistance in transferring history and training for all areas of the new system. I felt this was a very important step in the process, having a person who could talk the old system while explaining The Business Edge™. We converted over to the new system on Monday September 29, 2014 and have not missed a beat since. We have even been able to improve our Vendor Managed Inventory system.”

No Fanfare

Bud said, “We made no announcements to our customers of our conversion but we have received many compliments on our improved delivery of professional looking documents and the timely manner in which we now invoice customers. All of our “dot matrix” printers have been upgraded to high quality “laser printers” that print color at a fraction of the cost. No more pre-printed forms. All but one customer has been converted to emailed invoices – saving us thousands of dollars per year in pre- printed invoices, envelopes, stamps, and labor to put them together. “

100% Lot Control

“We elected to go with 100% lot control. Every part that is used for an order is lot controlled – selected and recorded. This step has all but eliminated any possibility of picking the wrong part. We don’t have to do physical inventories and don’t plan on ever doing one.

“The most important thing we’ve done in the recent past was the upgrade to our computer system. I truly believe that we’ve constructed a solid foundation that supports growth into the future. We identified a serious weakness in our ability to grow, fixed it, and are now ready to plot the next level of growth for Yankee.”

This article appeared in Distributor’s Link Magazine, Summer 2015

For More Information

Yankee Industrial

68 Daniel Webster Highway

Merrimack, NH 03054

Phone: 1-603-886-5700

Fax: 1-603-886-5710

bdurgin@yankeeind.com

www.yankeeind.com

Computer Insights, Inc.

108 South Third Street

Bloomingdale, IL 60108-2912

Phone: 800-539-1233

Fax: 630-893-4020

dcowhey@ci-inc.com

www.ci-inc.com