ET&F Receives ICC Recognition For Panelfast® Fasteners

ET&F recently received ICC recognition for their Panelfast® brand of fasteners for use in cold formed shear wall assemblies. This marks a significant step for the light gauge steel industry. Historically, pneumatically driven pins have been limited to use in shear walls resisting wind loads only. Working with ICC, ET&F led the pneumatic pin industry by developing criteria to facilitate reversed cyclic testing and development of shear wall design values for wood based panels attached to steel framing with pneumatic pins. ET&F pins have been tested to these criteria and have become the only pneumatic pins to be recognized for use in shear walls with seismic loading.

This new code report, ICC ESR- 1777, complements three other national code reports recognizing ET&F pins. These reports provide design values for horizontal plywood diaphragms, attachment of fiber cement siding, and fastening of gypsum based panels. These reports are a valuable aid to engineers specifying and designing cold formed steel and are often required to obtain building permits.

ET&F is a Long Time Industry Leader

Since 1982, ET&F has been developing, manufacturing and distributing specialty pneumatic tools and hardened steel fasteners for the construction industry. These innovative systems allow split second fastening to steel and concrete substrates without the need for predrilled holes or time consuming screwing techniques.

The company’s growth has been fueled in part by the increasing popularity of light gauge steel construction. Starting as a small division of a specialty fastener manufacturer, ET&F today is an independent company with its own national sales team, manufacturing plant, engineering department and proprietary products.

Pneumatically Driven Pins are Best for Some Applications

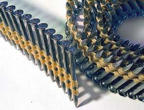

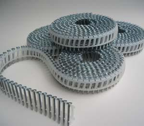

ET&F pneumatically driven fasteners called pins, are similar in appearance to common nails, but are made from high carbon, heat treated steel and have a ballistic point for penetration into the hardest substrates. Most of their fasteners are finished with Aericote® 1000 coating, which provides 1000 hours of salt spray test protection. For applications requiring greater corrosion resistance, a limited line of stainless steel fasteners are offered. Unique, built-in overdrive control on all ET&F tools allow even the softest of materials to be fastened without unwanted overdriving of the fasteners.

A popular use of the ET&F system is attaching James Hardie® Brand fiber cement siding to cold formed steel framing or directly to masonry walls. The labor savings using pneumatic tools for steel fastening is substantial when compared to the traditional method of self drilling screws. Abrasive ingredients in fiber cement like Portland cement and ground sand dull screw points, slowing down the screw’s ability to pierce steel. Pneumatically driven pins are not adversely affected when driven through fiber cement and will improve speed of installation over screw fastening. By increasing air pressure, thicker steel can be penetrated with no increased effort by the installer.

For attaching fiber cement siding directly to masonry, ET&F offers strip collated pins and a powerful strip nailer. This system eliminates the need for furring strips and complicated framing around doors and window openings. Extensive lab testing by James Hardie and ET&F has produced code recognized design values for these siding applications. Design parameters are available to resist basic wind speeds of up to 150 mph.

Other systems are available for attaching plywood to steel as heavy as 3/16”. Common applications are floor and roof assemblies in portable buildings or in utility trailers. The company also offers trim-style nailers and fasteners for attaching interior and exterior moldings and trim to both steel and masonry substrates. Rounding out the product line are coil nailers for attaching gypsum panels, insulation and wire lath to cold formed steel and for fastening steel to steel. The common characteristic of all of ET&F products is labor savings for the contractor. Fastening to steel and concrete can be done as fast as nailing to wood.

ET&F Fasteners Included in 4 National Code Reports

Code recognition of fasteners requires comprehensive quality control and lot number traceability which is verified through onsite manufacturing audits by code representatives. As ET&F has grown, so has the task of keeping data of wire lots, manufacturing records, inspection reports, heat treating results and corrosion testing.

New Software Makes Lot Control & Traceability a Snap

Recently, ET&F has purchased new computer hardware and software to help with this task. The BUSINESS EDGE software from Computer Insights is a fully integrated computer solution for fastener manufacturers. Its manufacturing module keeps lot traceability from the finished fastener back to the heat number of the raw wire, including all the steps along the way.

The company had outgrown their previous software and began looking for a new solution in 2006. As a long time STAFDA Associate member, ET&F utilized STAFDA’s Manufacturing Software Guide to identify several potential vendors. An important criterion in their decision was finding a company that understood fastener manufacturing and the unique aspects of fastener distribution. They found The BUSINESS EDGE to be that solution.

Computer Insight’s personnel have the knowledge of the fastener industry as well as of The BUSINESS EDGE, which makes training on the new system easy. Weekly sessions using ET&F’s own data eases the transition from the old software to the new system. ET&F is about 75% through the training process and all indications are that decision to change to the Business Edge is the right one. And, this training is available on an ongoing basis for new ET&F employees as the company continues to grow.

Scheduling, Inventory Control & Excellent Customer Service

The system provides scheduling of production machinery, better inventory control and detailed reporting of customer history. As a manufacturer which sells exclusively through distribution, ET&F understands the importance of controlling inventory. This is true for its own operation as well of the operation of its distributor customers. The BUSINESS Edge’s inventory module helps to optimize ET&F’s inventory based on lead times and customer demands. This permits ET&F to have the right product in the right quantity on hand.

In addition, ET&F field sales personal have remote access to the system providing them with up to the minute information regarding product availability and order status which ultimately provides better customer service. Salesmen can dial in from their own laptop or public computers from where ever they are any time of day for the information they need.

This article appeared in Distributor’s Link Magazine

For More Information

ET&F Fastening Systems, Inc.

29019 Solon Road

Solon, Ohio 44139

phone: 800-248-2376

www.etffastening.com

Computer Insights, Inc.

108 South Third Street

Bloomingdale, IL 60108-2912

Phone: 800-539-1233

Fax: 630-893-4020

dcowhey@ci-inc.com

www.ci-inc.com